Menu

Menu

Close

- 3D Printers

3D Printers

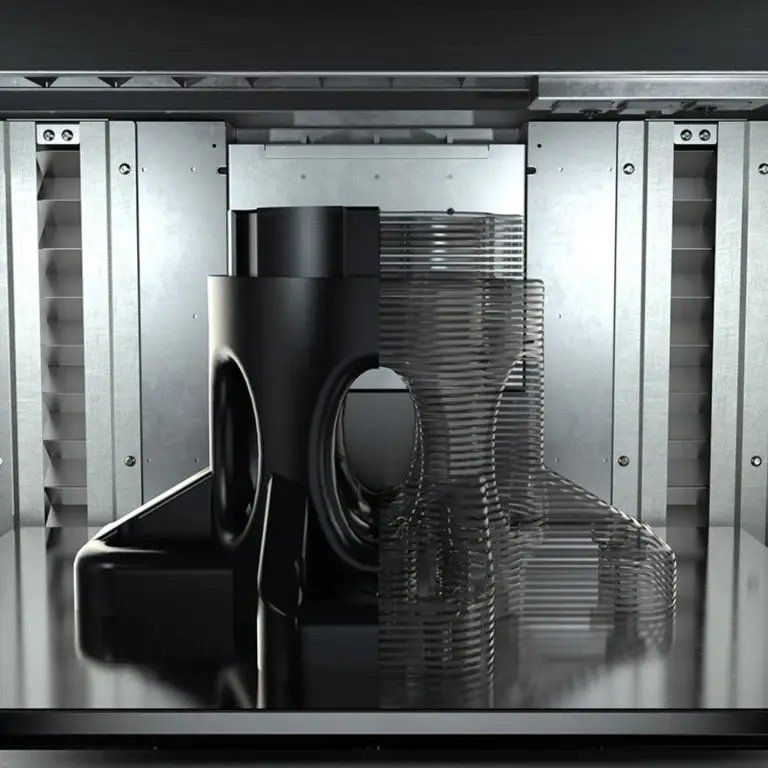

Metal 3D Printers

Industrial Composite 3D Printers

- Materials

Materials

Metal

Plastic

- Software

Software

Digital Forge Complete

Digital Source

- 3D Printers

3D Printers

Metal 3D Printers

Industrial Composite 3D Printers

- Materials

Materials

Metal

Plastic

- Software

Software

Digital Forge Complete

Digital Source